The distinct differences in tissue structure among vegetables, fruits, and leafy greens necessitate corresponding design adjustments in vegetable blanchers, which is a key factor driving price variations. For instance, soft fruits like tomatoes require structural protection to prevent skin damage during blanching; root vegetables demand stronger conveyor chains and more stable temperature control systems; while leafy greens need gentler circulating water flow to avoid leaf breakage. This diversity in structure and configuration naturally widens the gap between vegetable blanching machine prices tailored for different applications.

Heating Method Impacts Blanching Machine Price

Blanching machines typically utilize either electric heating or steam heating. The installation requirements, energy consumption levels, and equipment configurations associated with each heating method directly influence pricing. Steam blanching machine suits factories with existing boiler systems, significantly reducing energy costs. Electric heating features simpler structures and easier installation but consumes more energy during prolonged continuous production. Businesses must select configurations suited to their operational conditions, which also impacts overall budgets.

Production Capacity and Equipment Size Influence Overall Pricing

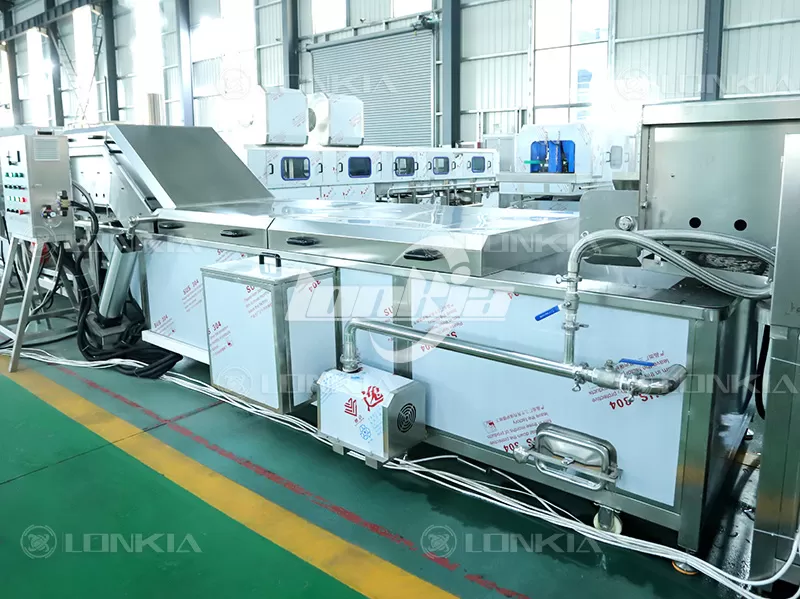

Higher processing volumes necessitate longer tank lengths, wider chain mesh widths, and larger water circulation systems, consequently affecting costs. Before inquiring about vegetable blanching machine price, customers should specify primary processing materials, hourly throughput, and processing workflow to enable manufacturers to provide accurate quotes. For instance, Lonkia customizes blanching temperature zones and conveyor speeds based on material characteristics and production requirements, ensuring vegetable blancher aligns with actual production needs and maximizing ROI.

Equipment Configuration Enhances Stability and Impacts Cost

The blanching machine's temperature control system, circulating hot water structure, insulation efficiency, and automatic water replenishment system all influence the final price. For fruit and leafy vegetable processing, precise temperature control minimizes over-blanching, preserving color and texture. For root vegetables, stable hot water circulation ensures uniform blanching. While high-standard configurations increase equipment costs, they significantly enhance product quality, reduce defect rates, and lower long-term losses.

How to Obtain More Accurate Vegetable Blanching Machine Price?

When inquiring about vegetable blanching machine price, businesses should provide details such as material type, processing volume, factory layout, and heating method requirements. Different materials necessitate distinct designs, so clear communication of needs enables vegetable blanching machine manufacturers to offer more suitable solutions. For factories aiming to enhance processing quality and efficiency, selecting brands with stable technology and mature designs—such as Lonkia—can reduce long-term maintenance costs and deliver a more reliable user experience.